What Are PFAS and Why Do They Matter in Wastewater Operations?

PFAS, or per- and polyfluoroalkyl substances, are a group of synthetic chemicals used since the 1940s for their resistance to water, oil, and heat. They are found in industrial coatings, nonstick cookware, stain-resistant fabrics, firefighting foams, and numerous other products.

PFAS are often called “forever chemicals” because they do not degrade naturally in the environment. They accumulate in soil, water, and living organisms. In wastewater systems, PFAS pass through traditional treatment processes and remain in effluent and biosolids.

These compounds have been linked to health risks such as certain cancers, immune system effects, developmental issues, and environmental persistence. For wastewater operators in NJ, PA, and NY, PFAS represent both a regulatory compliance challenge and an operational cost driver.

How Do PFAS Enter Wastewater Systems in the Tri-State Region?

In New Jersey, Pennsylvania, and New York, PFAS contamination in wastewater comes from multiple sources:

Industrial Discharges

Chemical manufacturing plants

Textile mills producing stain-resistant fabrics

Metal plating operations using PFAS-based surfactants

Firefighting Foam Runoff

Airport facilities

Fire training centers

Industrial fire suppression systems

Landfill Leachate

PFAS-containing waste in municipal and industrial landfills

Leachate sent to treatment plants without PFAS pretreatment

Domestic Wastewater

Consumer products containing PFAS washed into the sewer

Laundry from clothing treated with PFAS-based coatings

Cleaning and personal care products with PFAS

Stormwater Infiltration

Runoff from PFAS-impacted sites entering combined sewer systems

What Are the 2025 PFAS Regulations in New Jersey, Pennsylvania, and New York?

New Jersey PFAS Rules (2025)

The New Jersey Department of Environmental Protection (NJDEP) has some of the strictest PFAS regulations in the country.

Pennsylvania PFAS Rules (2025)

The Pennsylvania Department of Environmental Protection (PA DEP) is expanding PFAS oversight.

New York PFAS Rules (2025)

New York’s Department of Environmental Conservation (DEC) and Department of Health (DOH) are coordinating enforcement.

What Operational Challenges Do PFAS Regulations Create?

Testing Costs and Complexity

Certified laboratory analysis for PFAS can cost $300–$500 per sample

Special handling requirements increase labor needs

Sludge Management Restrictions

Land application bans or limits for PFAS-impacted biosolids

Higher landfill tipping fees for sludge disposal

Treatment Process Adjustments

Additional filtration or adsorption steps

Increased chemical usage in some processes

Staff Training Requirements

Specialized sampling protocols

Understanding new permit conditions

Regulatory Scrutiny

Higher frequency of inspections and reporting

What Treatment Technologies Can Remove PFAS from Wastewater?

While no single solution fits every facility, these technologies have proven effective for certain PFAS removal goals:

Granular Activated Carbon (GAC)

Widely used for PFAS adsorption

Requires periodic media changeouts

Ion Exchange Resins

High selectivity for specific PFAS compounds

Can complement GAC systems

Reverse Osmosis (RO)

Removes broad range of PFAS

Generates concentrated brine waste

High-Temperature Incineration

Used for PFAS destruction in solids

Limited availability and high cost

Emerging Technologies

Electrochemical oxidation

Plasma-based treatments

Novel sorbents

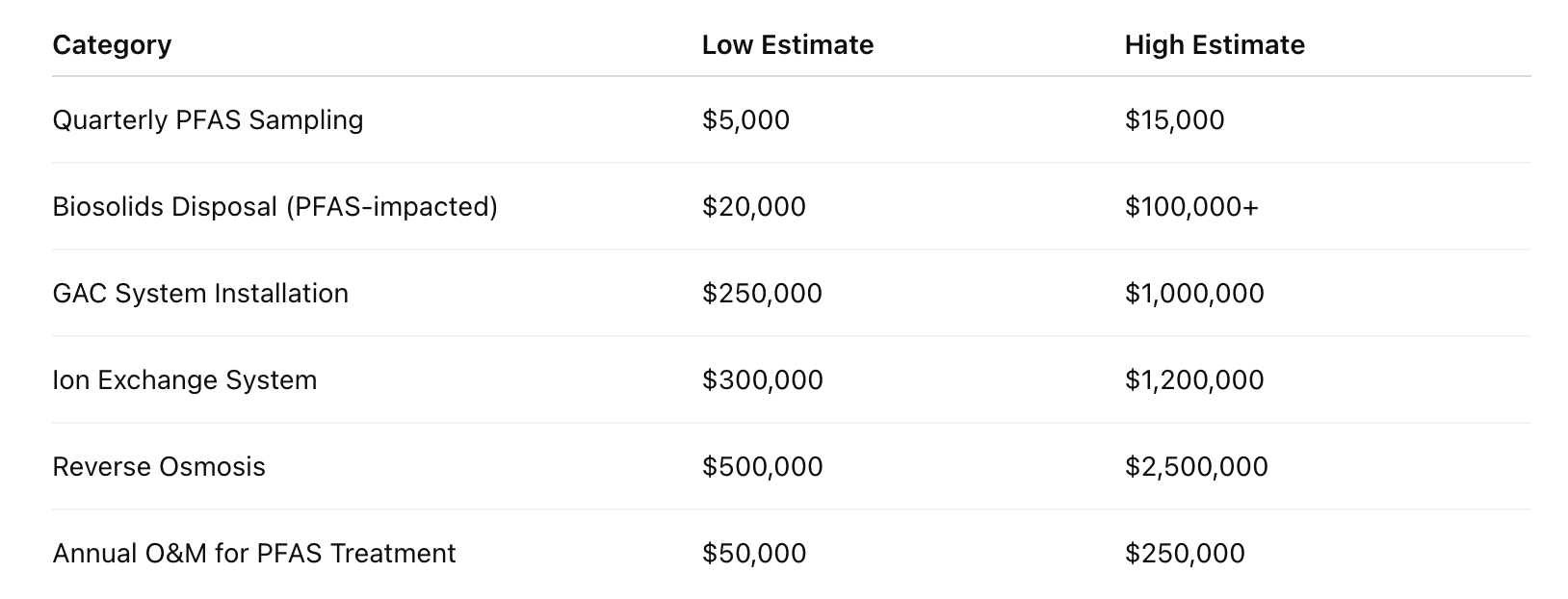

How Much Does PFAS Compliance Cost?

Costs vary by facility size, PFAS levels, and treatment needs. Approximate annual cost ranges for a mid-sized municipal facility in NJ, PA, or NY:

Case Example: PFAS Monitoring at a Mid-Sized NJ Facility

A municipal wastewater treatment plant in central New Jersey, processing 4 MGD, was required to begin quarterly PFAS sampling in January 2025. Initial results showed elevated PFOA and PFOS from industrial sources.

Actions taken:

Conducted industrial pretreatment inspections for all permitted users

Identified a metal finishing facility as the primary contributor

Required installation of on-site ion exchange pretreatment

Reduced influent PFAS levels by 60% within two quarters

Step-by-Step Checklist for PFAS Compliance in NJ, PA, and NY

Review your current NJPDES, SPDES, or NPDES permit for PFAS conditions.

Establish baseline PFAS levels in influent, effluent, and biosolids.

Identify potential PFAS sources in your service area.

Engage with industries on source control measures.

Evaluate treatment technologies for feasibility.

Train staff on PFAS sampling and handling.

Budget for testing, treatment, and disposal costs.

Maintain detailed PFAS monitoring records.

Communicate regularly with regulators.

Update your PFAS plan annually.

Why Local Expertise is Critical

Each state has unique permit structures, enforcement approaches, and disposal rules. A compliance strategy that works in Pennsylvania may fall short in New Jersey or New York. Local experience is essential to avoid costly missteps.

O&M Solutions specializes in wastewater operations and maintenance across the tri-state region. We help facilities navigate PFAS regulations, design effective compliance programs, and manage treatment solutions.

Conclusion

PFAS regulation is reshaping wastewater operations in New Jersey, Pennsylvania, and New York. Facilities that take early, decisive action will be better positioned to meet evolving permit requirements, control costs, and maintain regulatory compliance.

To schedule a PFAS readiness assessment for your facility, contact O&M Solutions today.